Lab Equipment

Principal Equipment

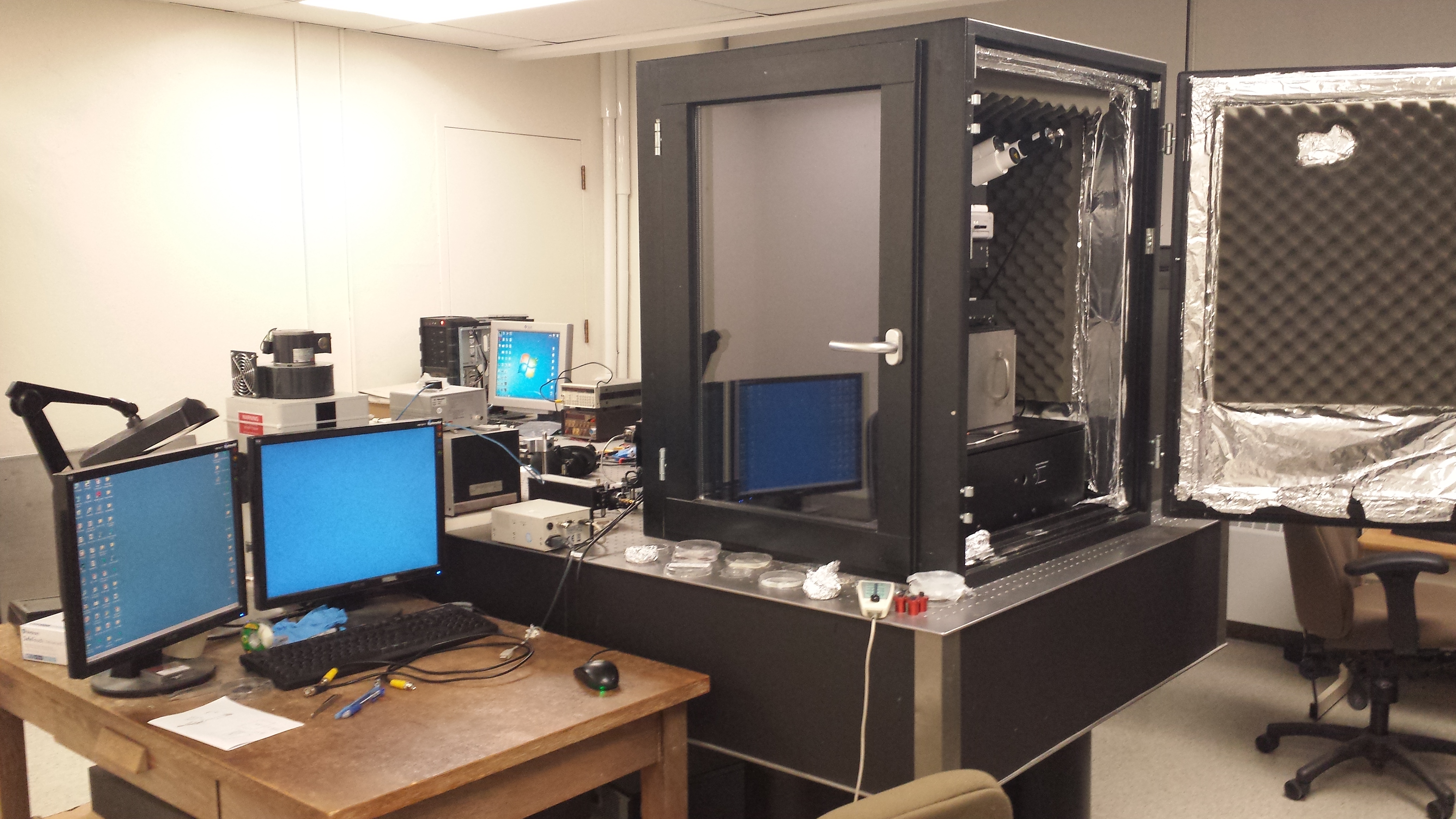

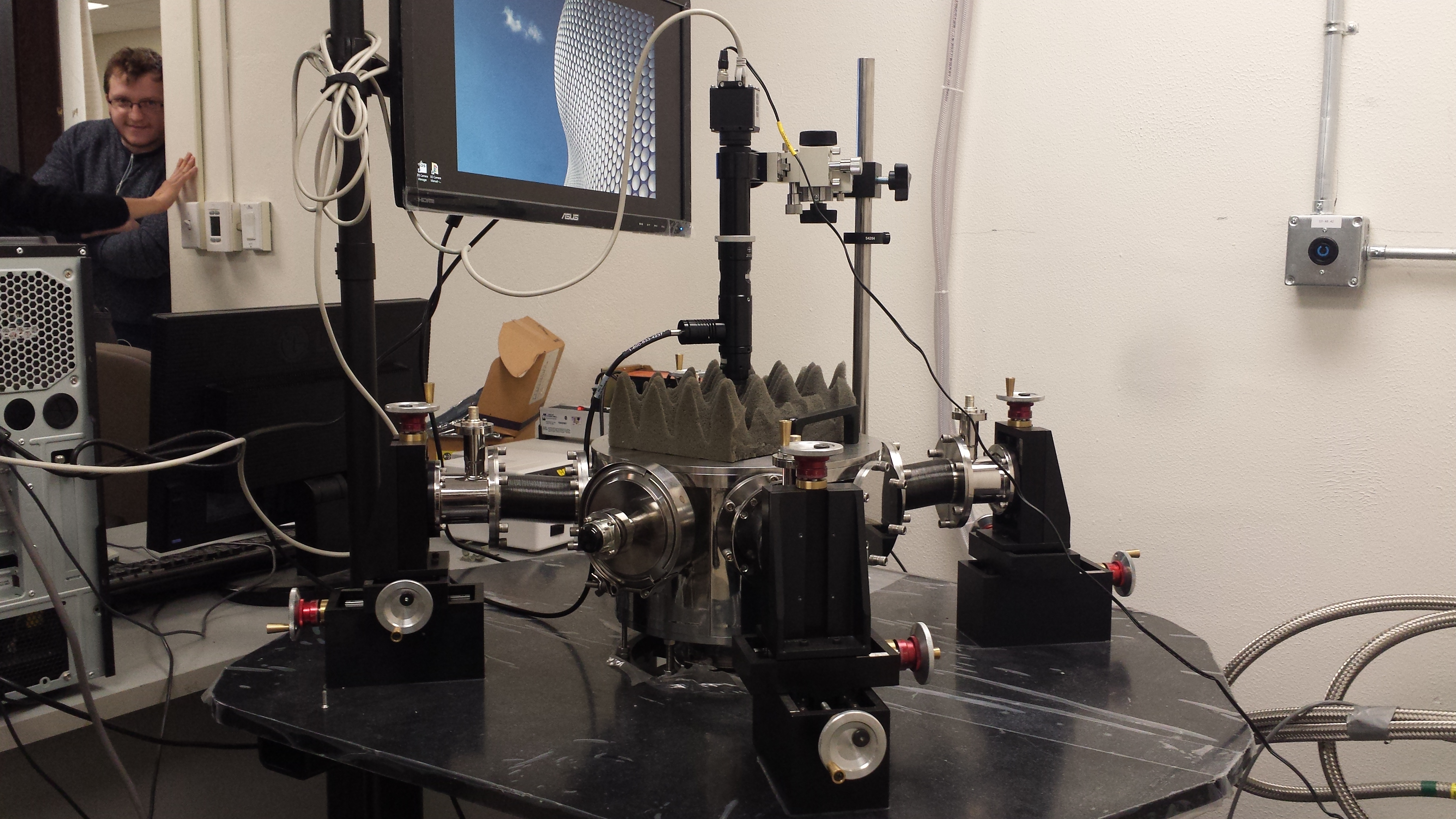

AFM/NSOM Microscope with KPFM and NeSTRI capability

alpha300S

WITec GmbH

AFM is a powerful tool that can be used to characterize electrical, structural and magnetic properties of materials at the nanoscale. Topographical images of a sample surface are produced by moving a nanometer sized imaging tip across the sample in a raster pattern. The distance between the tip and sample is carefully controlled such that the tip and sample surface interact to repel the tip. Perturbations in the position of the tip as it moves over the sample surface are converted to a topographical map through software. This system can also be coupled with specialized tips to perform other types of measurements including but not limited to Kelvin probe force microscopy (KPFM) that measures the local surface energy of a material, near-field scanning optical microscopy (NSOM) which uses specialized tips to collect optical images with nanoscale resolution beyond the diffraction limit, and magnetic force microscopy (MFM) that is used to image the local magnetic domains of a material.

For examples of published research using this system see:

[87], [98], [99]

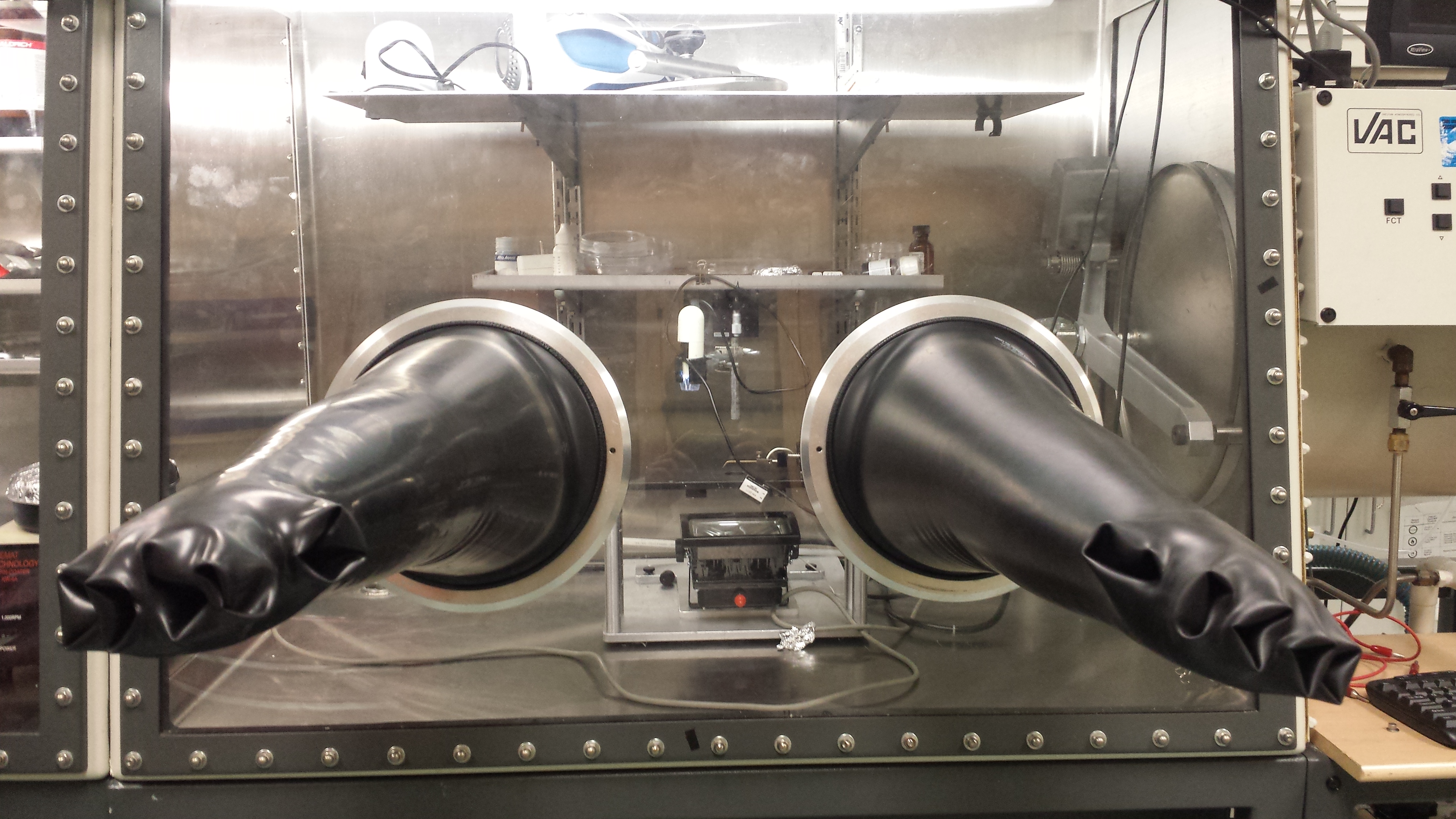

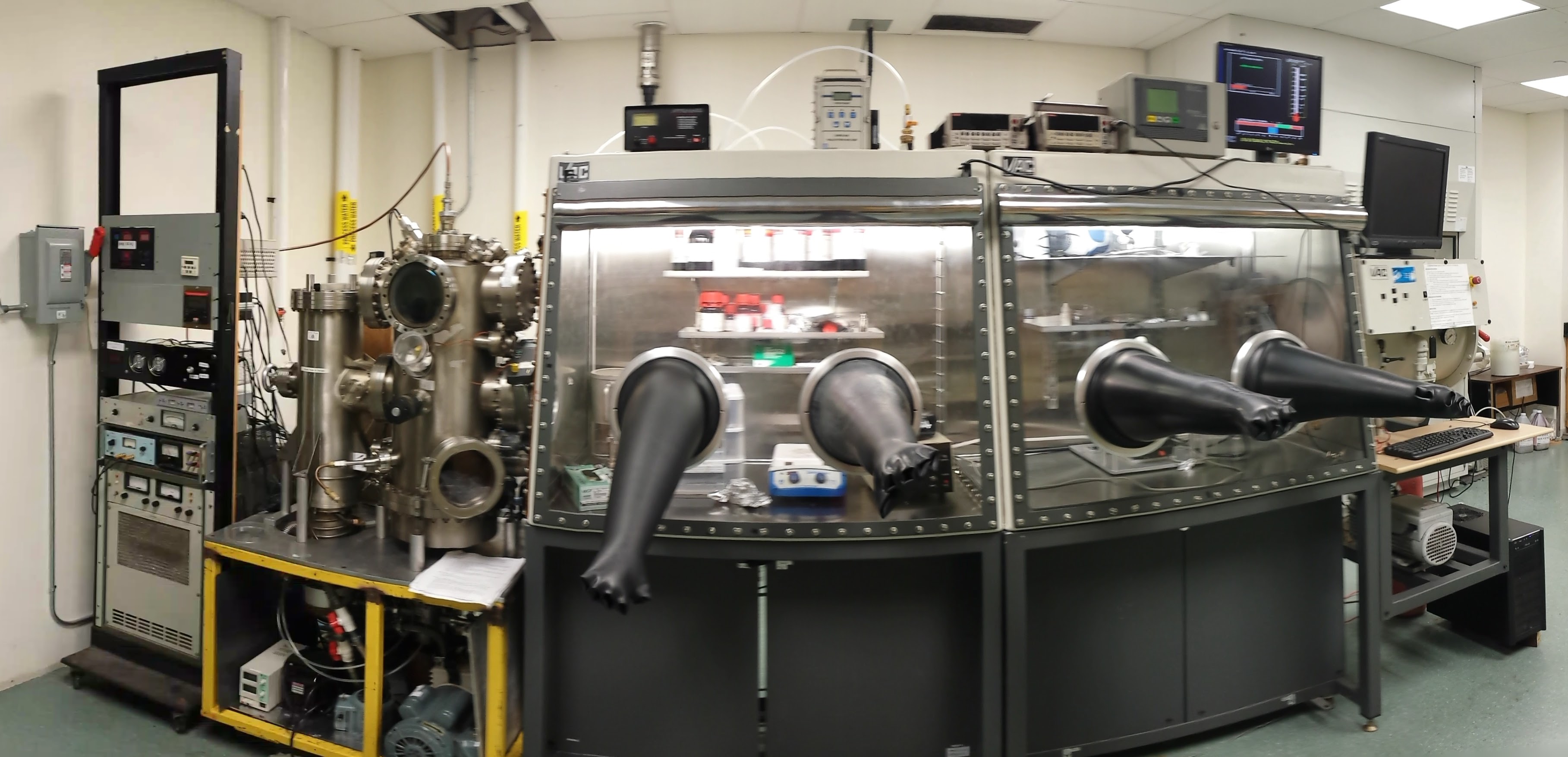

Dual Glovebox + Integrated Thermal Evaporator + DC-bias Radio-Frequency Sputtering System

Nexus

Vacuum Atmospheres Co.

The glovebox provides an environment with controlled humidity and atmosphere for sensitive experiments. Typically filled with nitrogen or argon, the glovebox is used for preparation of thin film devices including solar cells, thin film transistors and memristors to prevent oxidation of sensitive materials or other environmental degradation. The glovebox is integrated with a high vacuum chamber outfitted with thermal evaporators and an RF sputtering system for growing metal or organic thin films with thickness controlled to the nanometer. The integration with the glovebox allows materials and substrates to be passed directly into the vacuum chamber without exposure to air.

For examples of published research using this system see:

[86], [91], [95], [104]

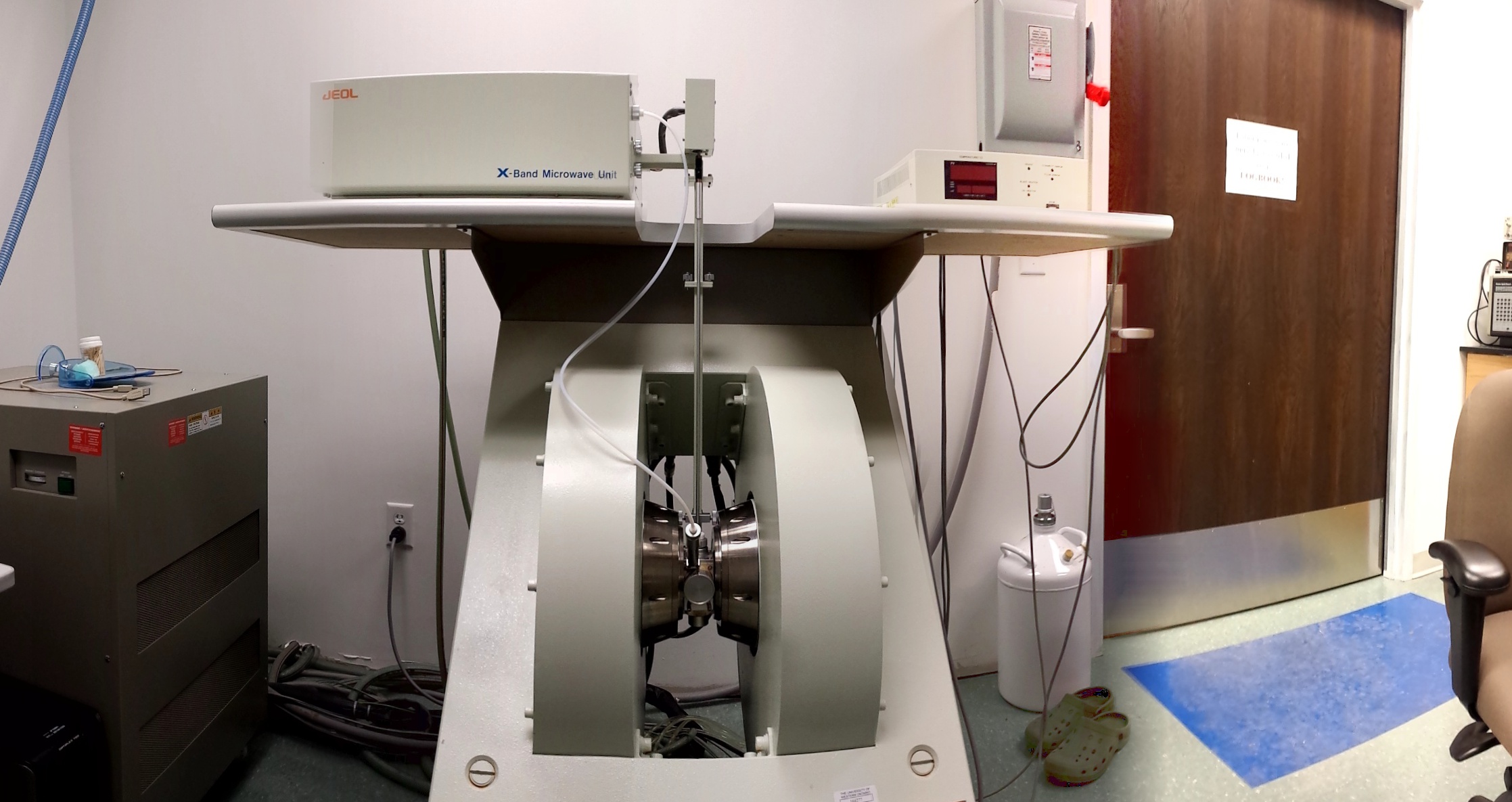

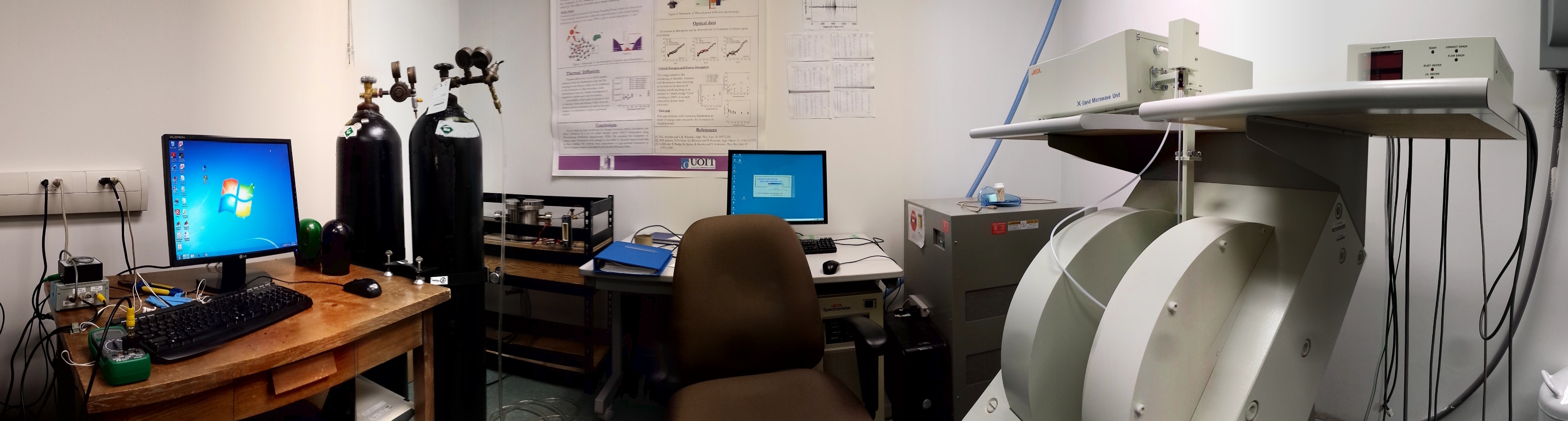

ESR Spectrometer

JES-FA200

JEOL Ltd.

Electron spin resonance (ESR) is a technique used to measure free electron ‘spins’ in a material, similar to how the nuclear spin is probed in nuclear magnetic resonance (NMR). ESR is used to probe the concentration of free spins in paramagnetic materials or organic free radicals that intrinsically contain unpaired electrons with free spins. ESR probes the concentration of free spins by measuring the amount of microwave radiation that is absorbed by the sample when it is put under a large magnetic field. The large magnetic field produces energy levels that can absorb microwaves, where the microwave absorption is proportional to the number of free spins in the material. ESR is a highly sensitive tool for investigation of dilute paramagnetic materials in solid or liquid states.

This system is also outfitted with a low temperature cryostat capable of cooling samples to -170°C using liquid nitrogen, which greatly enhances the ESR signal and allows for measurements where no signal whatsoever can be observed at room temperature. Other additional equipment is available including sample heating up to 200°C and an electrochemical flat cell for conducting electrochemical studies with simultaneous ESR measurements in situ.

For examples of published research using this system see:

[94], [103]

Low Temperature Probe Station

PS-VC-SS10-6

Advanced Research Systems, Inc.

Other Equipment

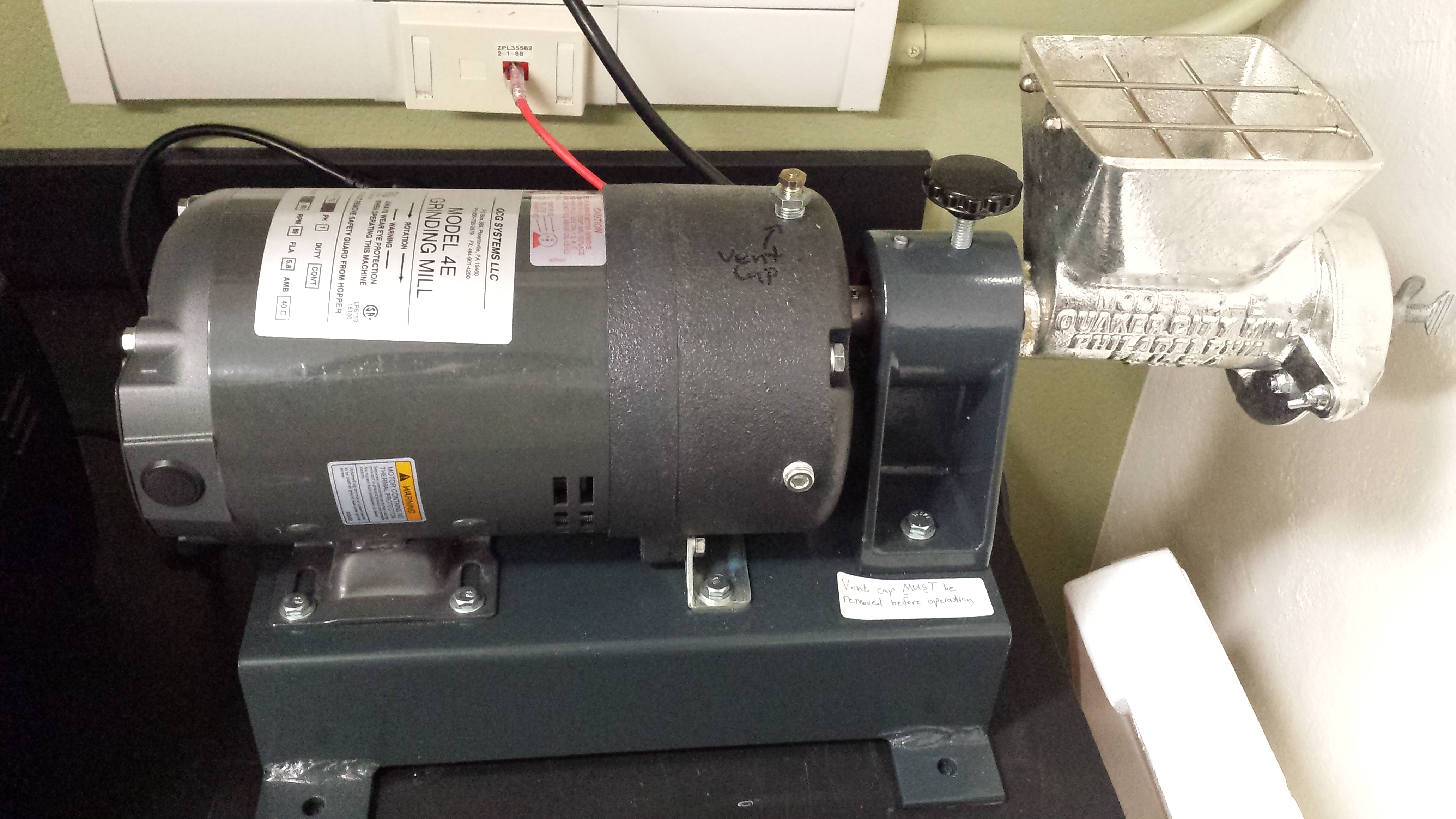

Grinding Mill

Model 4E

QCG Systems, LLC

Nanoparticle size has a great impact on the properties nanoparticles have. Samples that have passed through industrial processing may have larger particle size tolerances than we do. Our grinder can help control solid particle size in our samples.

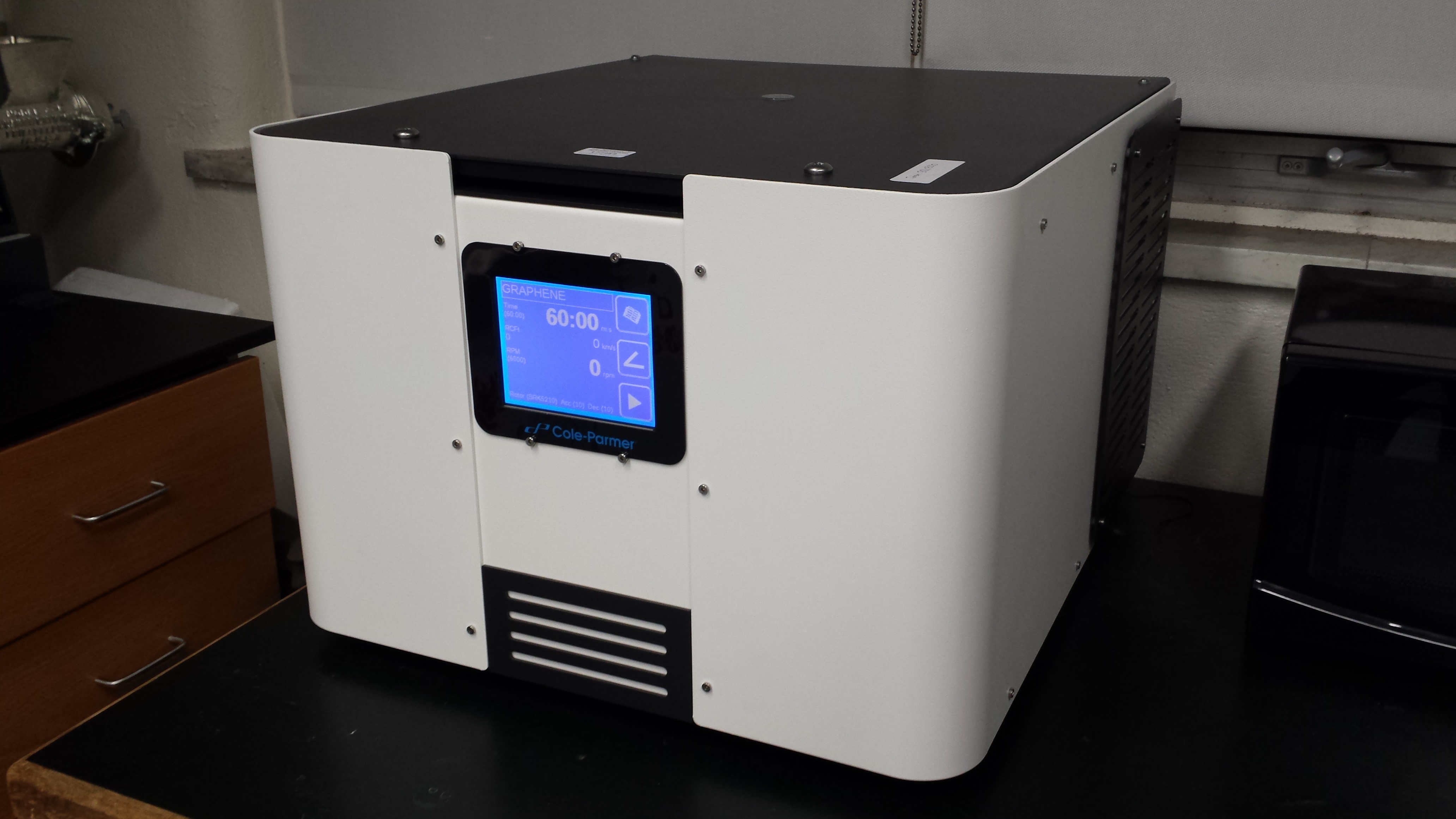

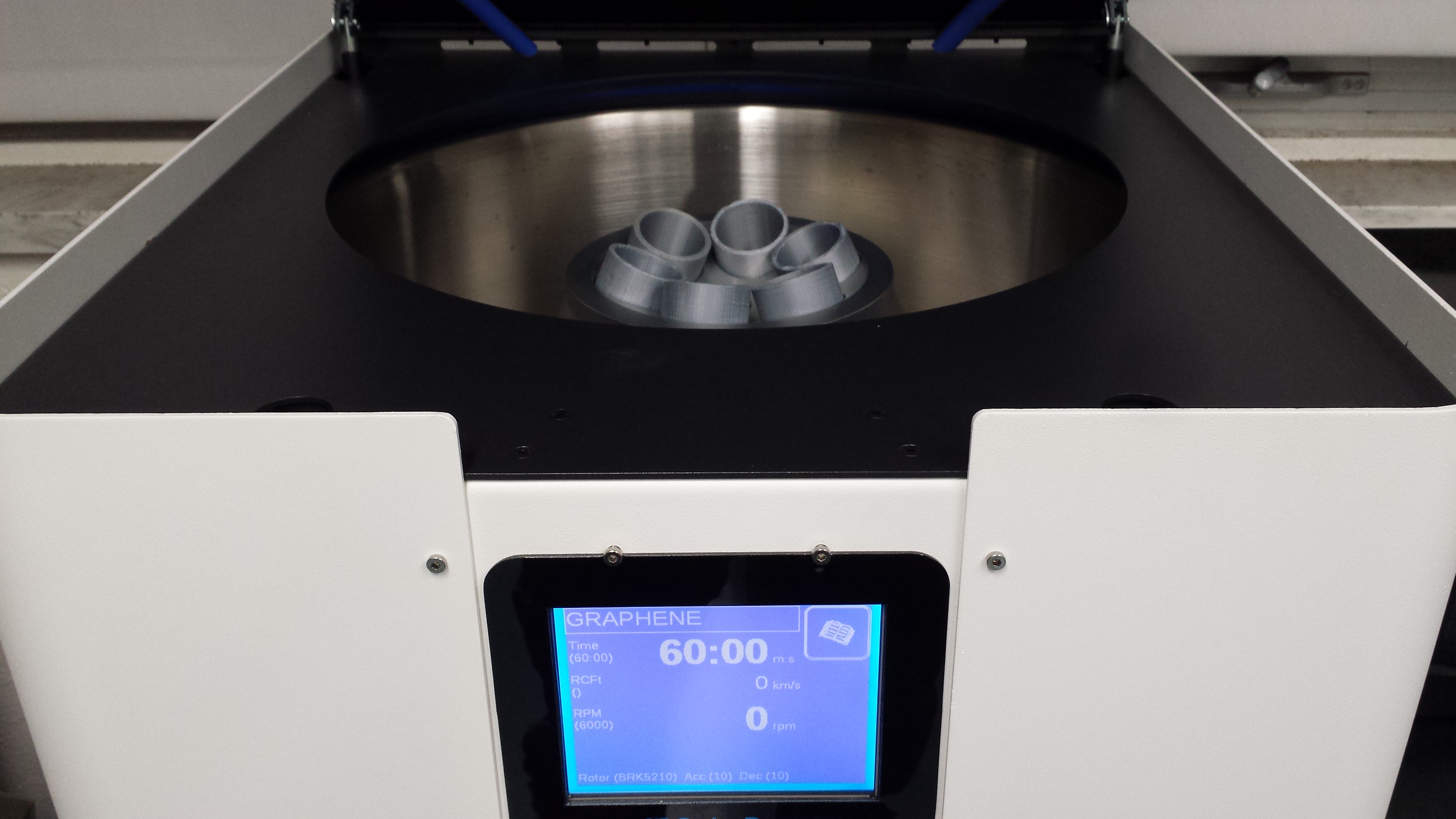

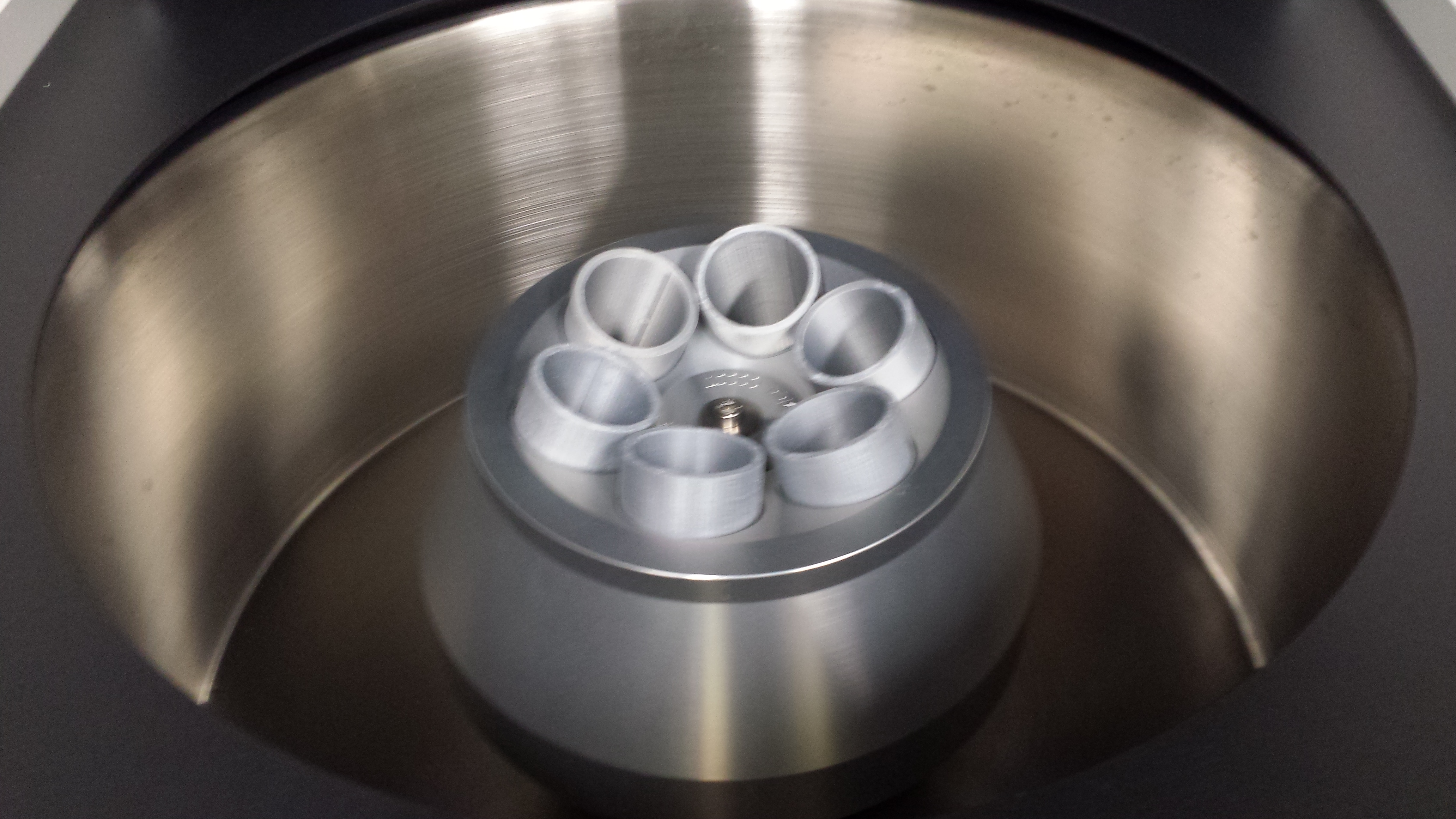

Research Centrifuge

K242

Centurion Scientific Ltd.

Liquid samples with suspended solids can be centrifuged to separate the solids from the liquids. This centrifuge has a maximum speed of 10,000 rpm. Our group uses centrifugation on samples where particle size matters, as even within nanoparticles there can be particles too large to have the properties we need.

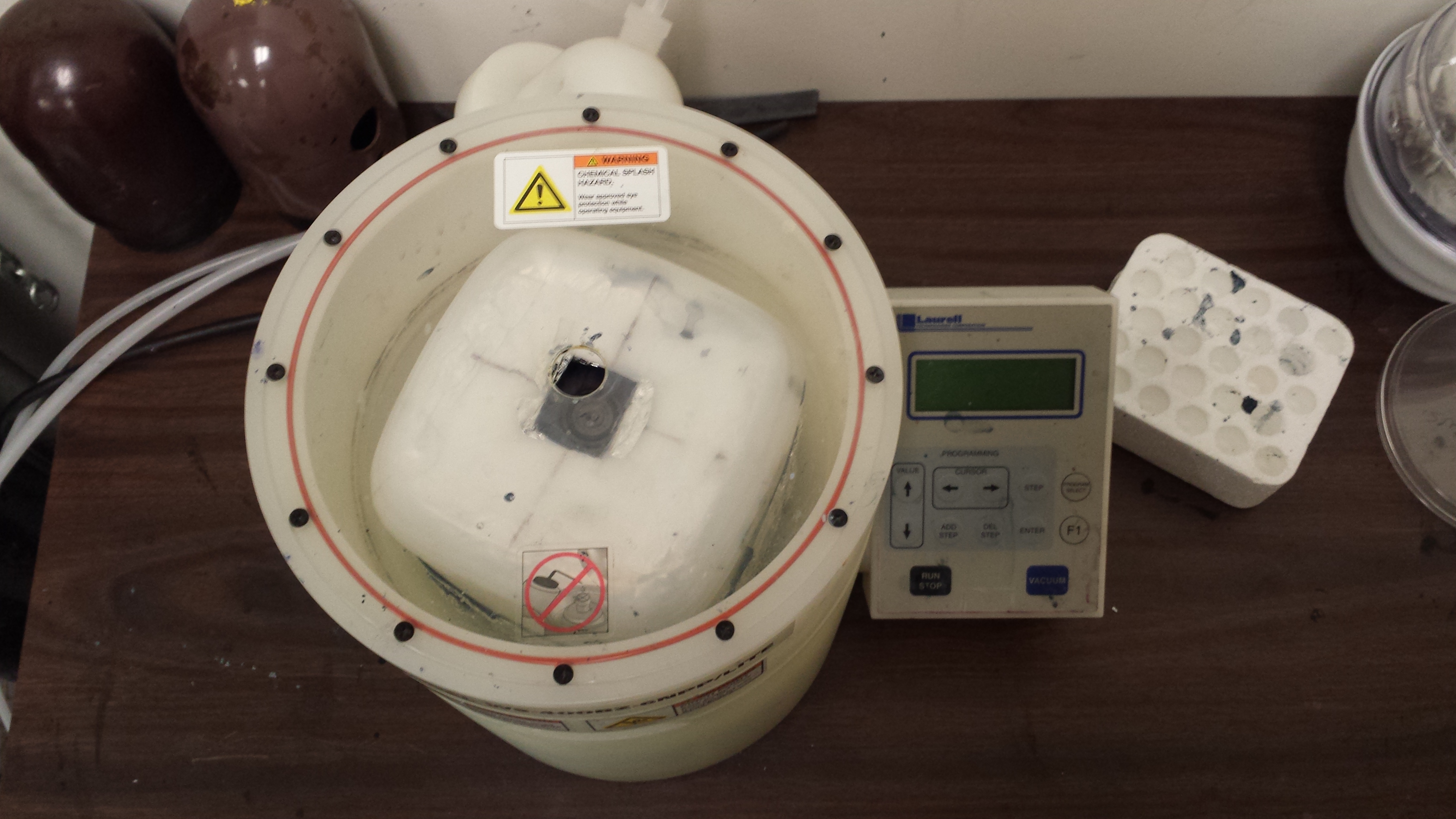

Spin Processor

WS-400BZ-6NPP/LITE

Laurell Technologies Corp.

Many semiconductor devices are composed of thin film multilayers. A spin coater is used to spread a layer of coating material onto a substrate through the centrifugal force generated from spinning. Group members working on semiconducting devices will find the spin coater fast and easy to use, making it invaluable.

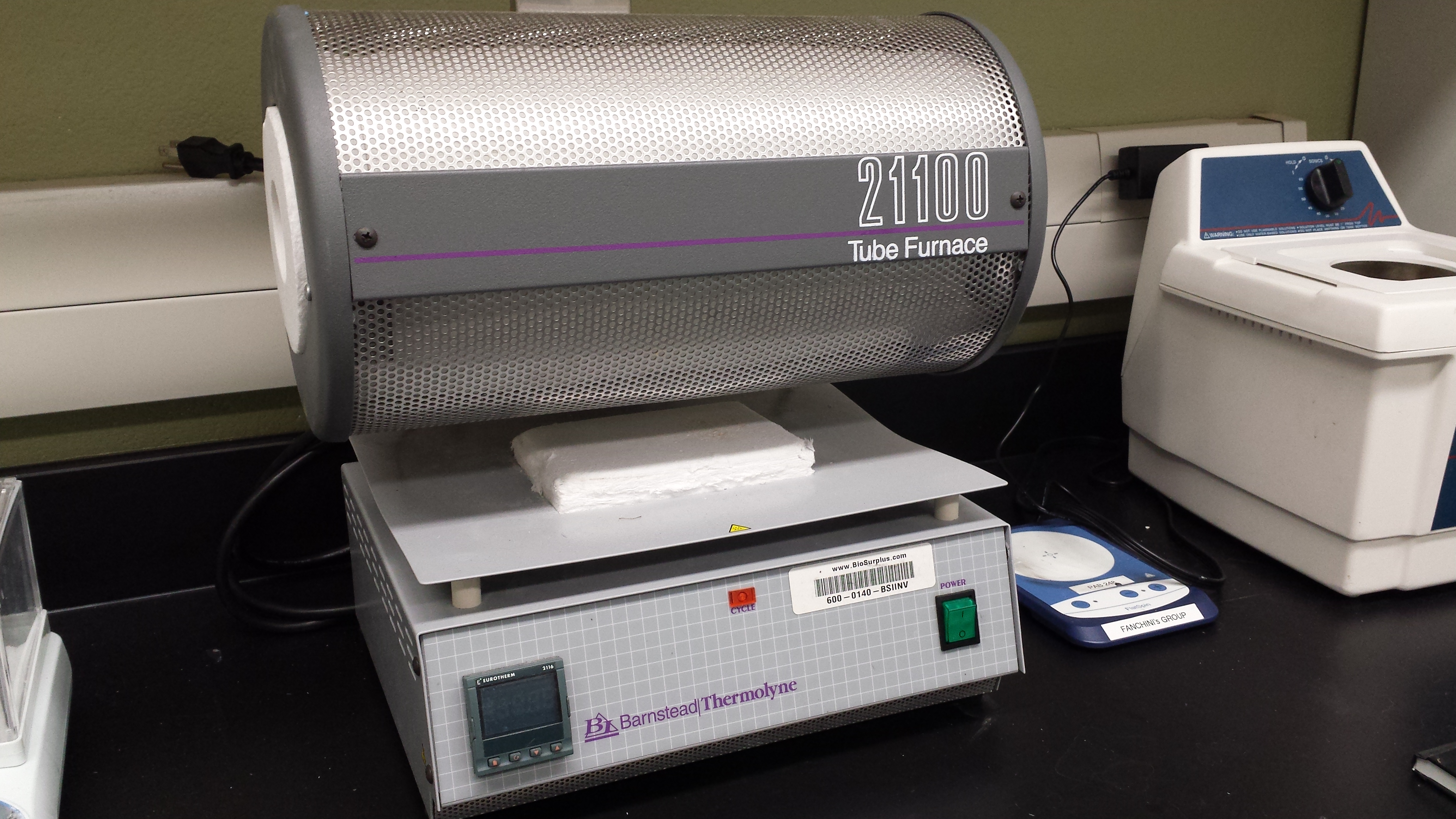

Tube Furnace

21100

Barnstead Thermolyne Corp.

This furnace has a maximum temperature of 1,200 °C, making it applicable to a variety of experiments that can be conducted in air. The tubular shape allows for glass tubes that are part of an external experiment to be passed through.

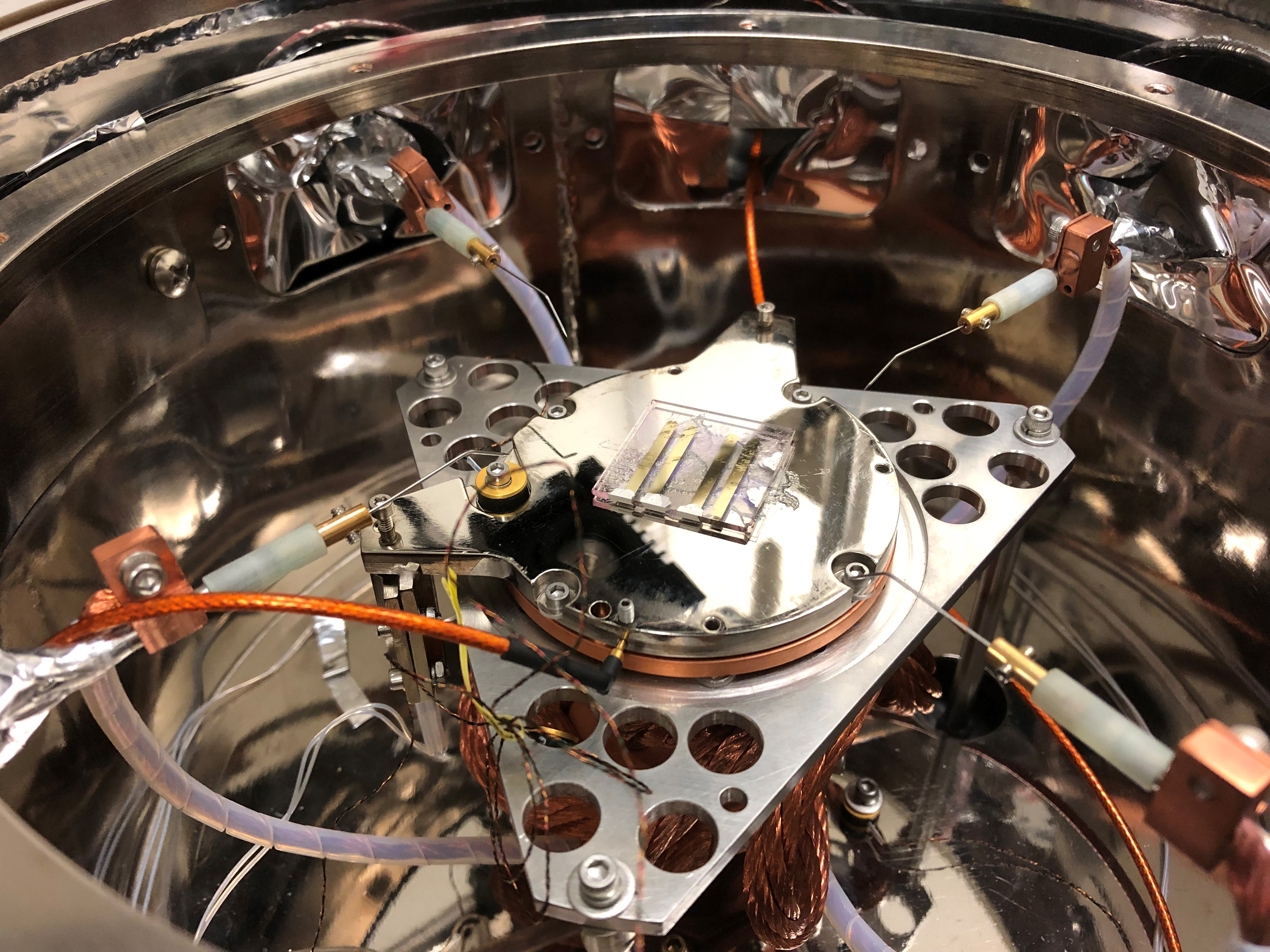

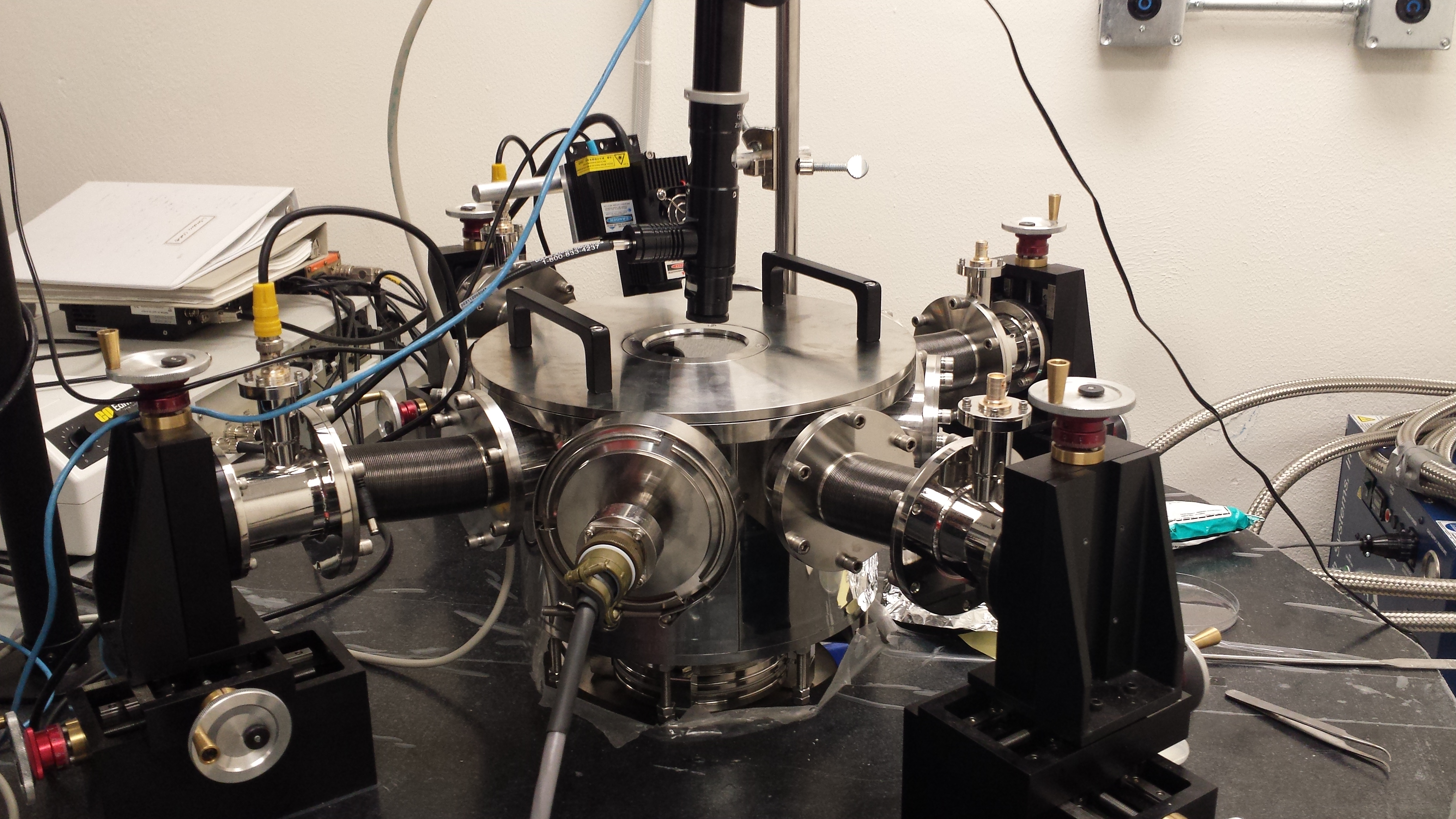

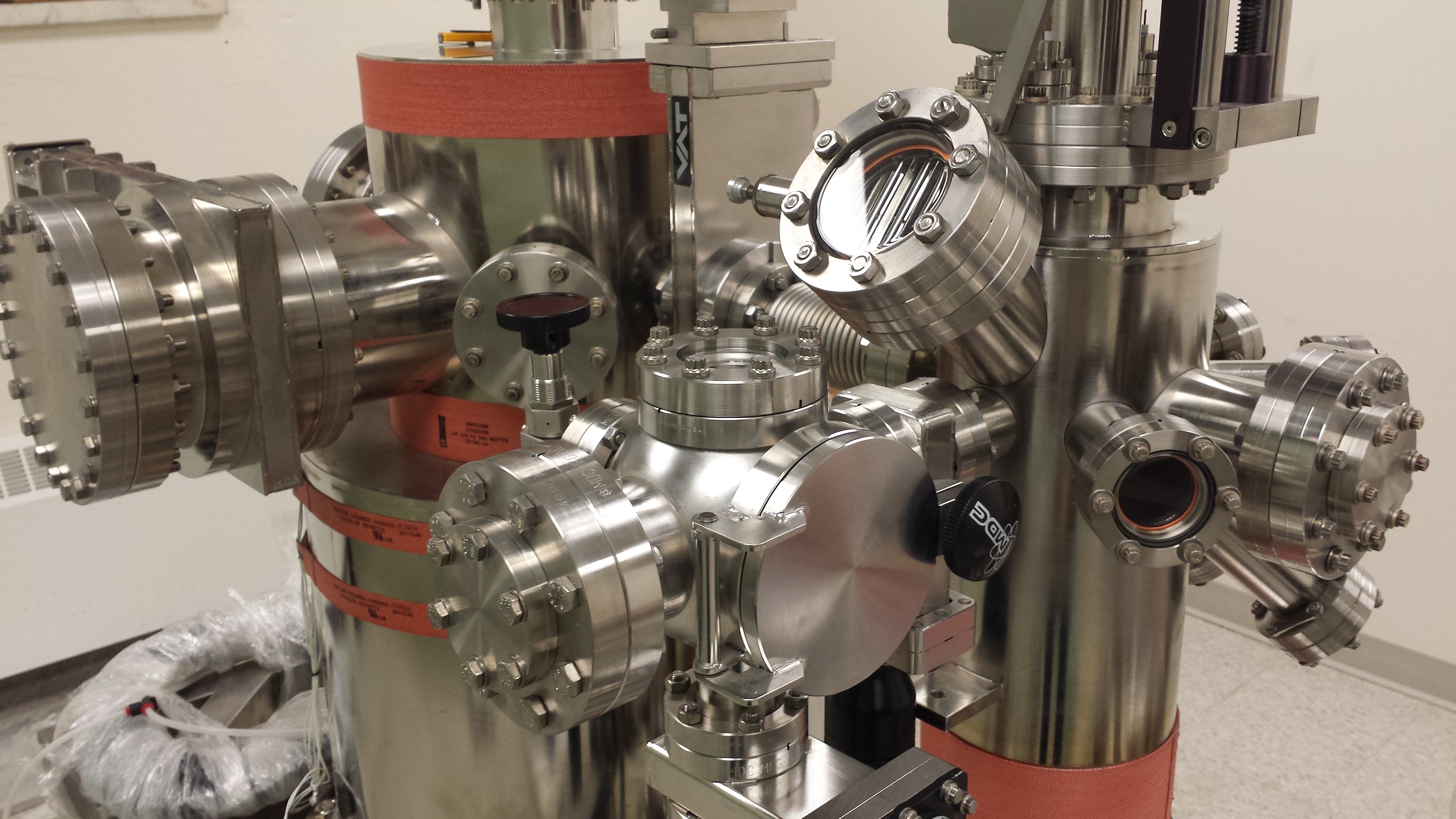

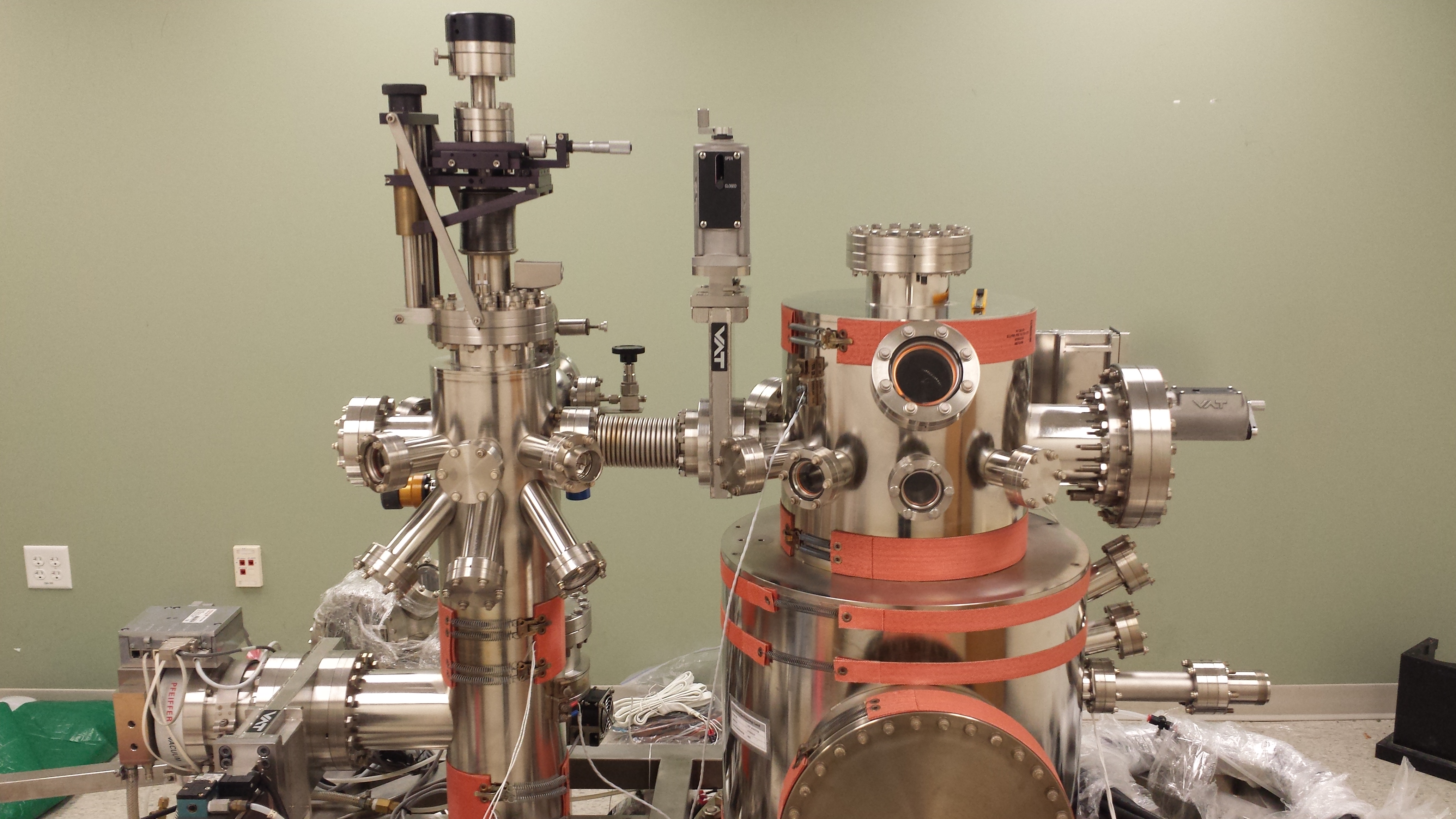

Ultra-High Vacuum AFM/STM

UHV AFM/STM

Omicron NanoTechnology GmbH

Ultrasonic Cleaner

Branson DHA-1000

Emerson Electric Co.

Our bath sonicator is the workhorse of countless experiments. Any item put into the 10 gallon water bath is blasted with 40kHz ultrasound to agitate and dislodge any small particles adhering to a surface. The DHA-1000, while designed for cleaning, is also effective at dispersing solid nanoparticles into liquids, making it an essential piece of equipment to nearly all group members' research.

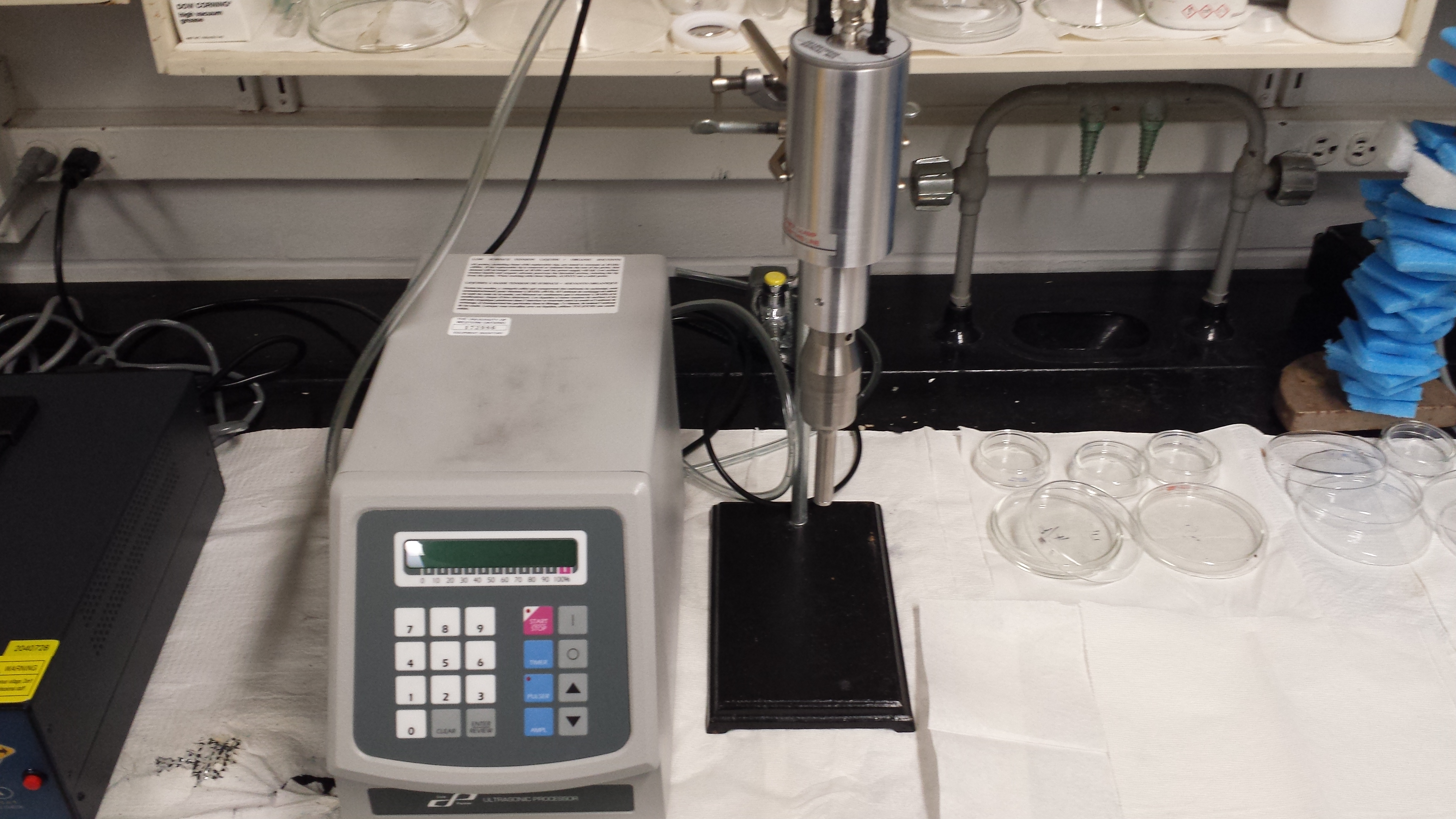

Ultrasonic Processor

CP750 and CV334

Cole-Parmer Instrument Company, LLC.

Similar to the Ultrasonic Cleaner, this sonicator uses ultrasound waves to disperse solid nanoparticles into liquid. However, this sonicator works by submerging a metal tip vibrating at 40kHz into the sample liquid. The high wattage output of this sonicator means that samples are sonicated much faster than what can be achieved with a bath sonicator.

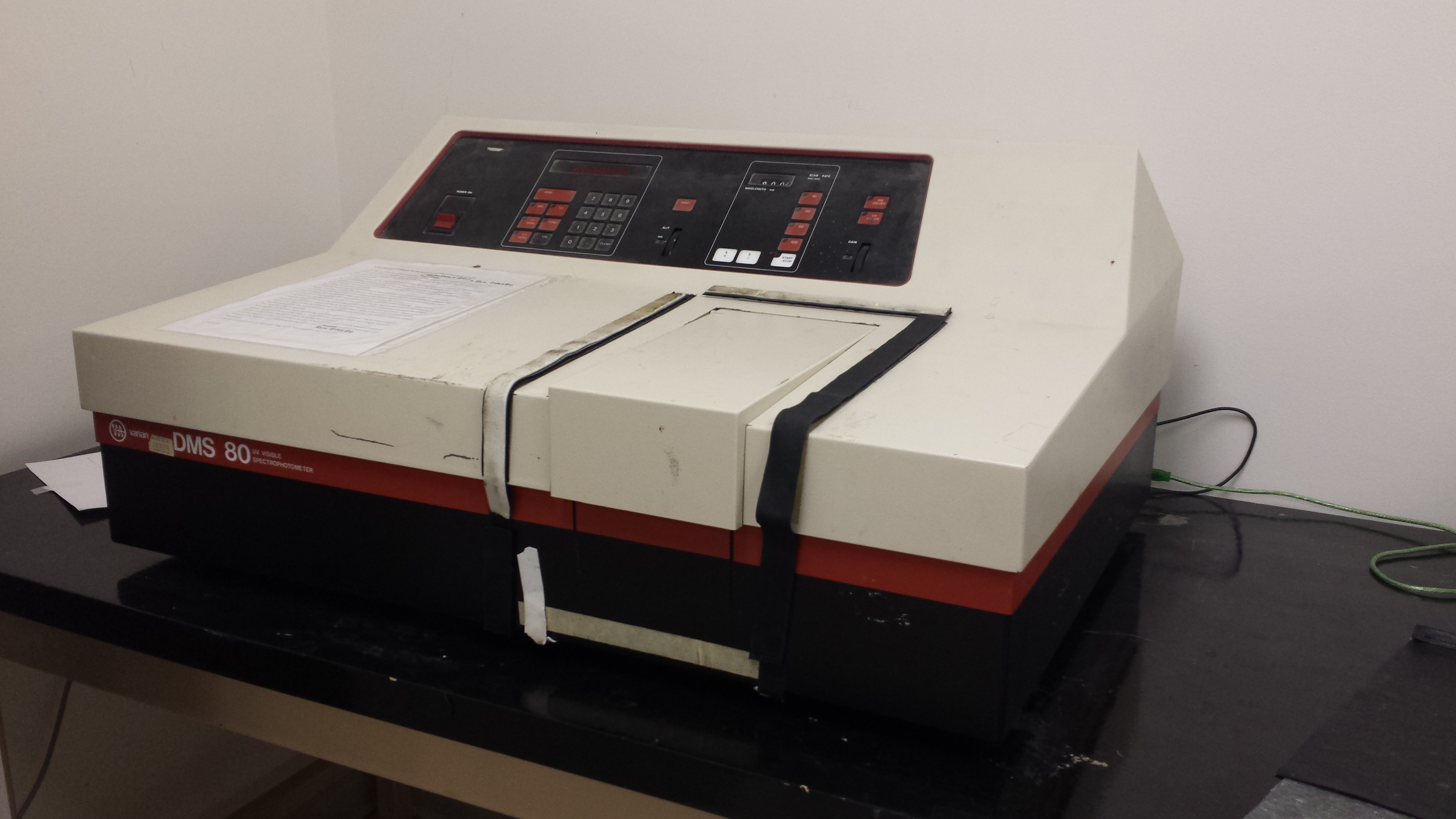

UV-Visible Spectrophotometer

DMS 80

Varian Inc.

Spectrophotometry is a quick way to characterize thickness of a solid sample or concentration in a liquid sample. The DMS 80, in conjunction with a computer, provides the ability to measure transmittance of solid and liquid samples as a function of either wavelength or time.

Vacuum Filtration Apparatus for 2D Material Thin Film Deposition

various

Vacuum filtration is the technique used to deposit thin films of various nanomaterials onto a filter. From the filter, materials can be transferred to their final substrate. It is vacuum filtration that allows us to extract nanoparticles from liquid suspension to produce characterizable materials. It is also a core component of our water filtration research. Given its ubiquitous nature, vacuum filtration is a simple yet critical part of our research.